Tough Field Testing in the Louisiana Bayou

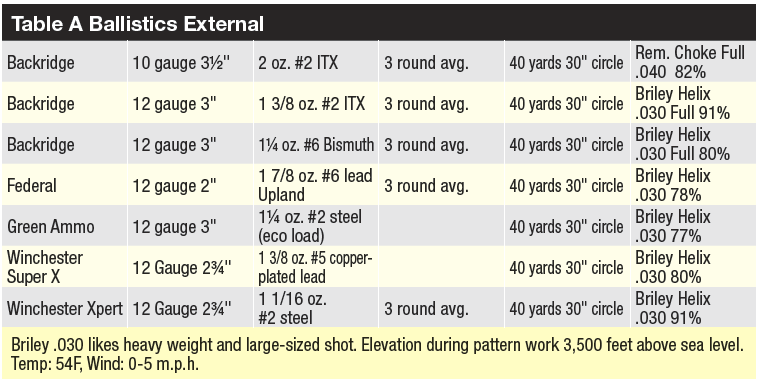

A week of pattern work at Backridge Ammunition Tennessee, another week in western South Dakota of the same and additional pattern work got the new Briley high-performance Helix hunting chokes up and running for the big swamp test series that would last almost 10 days.

When I asked the good folks at Briley, the famous Houston-based aftermarket shotgun equipment manufacturer, about a new direction in hunting choke design the company just might be taking, they were quick to respond. In short order, I had three of the new Helix design-based hunting choke tubes at my door ready for some testing. Some folks are too young to remember, but Briley was a company instrumental in getting safe and effective steel shot compatible chokes off the design table and to waterfowl hunters’ guns in the early years of the federally mandated non-toxic shot requirement.

Hunting chokes are nothing new to this choke manufacturer. However, these days most know them as a builder of clay target screw-in chokes, sub-gauge tube sets and other fine accessories that are quality gear for the serious clay target sports.

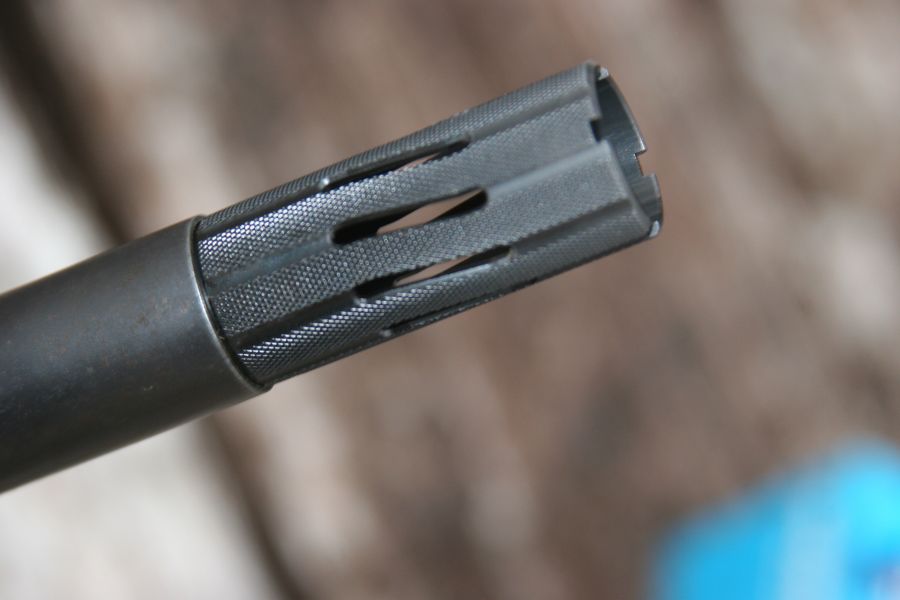

For 2020, Briley has come up with what they call “The Tower of Doom” Helix choke tube system. This choke is offered in three levels of pattern performance control. The choke tube is machined with long slits at an angle. The porting is touted by the manufacturer to rotate the total shot column prior to leaving the bore. This rotation is said to cause the pellets to move to the center of the pattern and fill in the core versus becoming flyers or blowing holes in the pattern.

The choke is an extended design that protrudes 2″ beyond the muzzle and has a total length of 4.5″. This choke is not your standard flush-mounted steel tube but an extension of the total choke tube design. Because hunting loads are far more massive in payload and propellant quantities than target loads, the design approach becomes a different type of problem.

Performance Patterning

Pattern work for the field testing of the Briley Helix choke began at the Backridge Ammunition plant just outside Nashville, Tennessee. Backridge had invited me to participate in a two-week hunt and consulting event while covering some new loads of theirs for 2020. These new Briley chokes were selected to perform the bulk of the testing in the 12-gauge loads. I discovered both of the more-open chokes, the close-range .005 (skeet) and the mid-range .015 (light modified), were shooting quite open when the Backridge 2¾”, 1¼ oz. Bismuth #6 loads were fired through the chokes. I assessed the situation and determined the Browning BPS was not taking a liking to either tube much beyond 30 yards, but again that is the range they were designed to accommodate.

With a move to the .030 tube, there was some noticeable increase in core density and pattern, including those of the #6 Bismuth. Other lead loads were shooting about 73% patterns with most gaps in the pattern disappearing altogether. I must also admit weather conditions were dreadful with wind, wet cold and trips made often to the shop office for some coffee and warm air.

South Dakota

Returning to South Dakota and shooting on several very nice 58 degree days with zero wind, things were improving in terms of that third .030 tube. Installed in the muzzle of my Winchester Super X II with a 28″ barrel, the choke shot like wildfire. The #6 loads at 1¼ oz. returned 82% at 40 yards with nice uniform core patterns which were very workable for ducks over decoys based on my shooting needs. When a switch was made to #4s in 1¼ oz. ITX shot, the patterns held nicely and several of them were printing in the high 80s.

On the final run with a jump to 1 3/8 oz. 3″ #2 ITX being the primary load, I would haul into the swamp country for coyote and nutria (super rats). The patterns ran from 91% to a pure 100% of the payload inside a 34″ area on the 40-yard pattern board surface. A coyote target head and neck, for example, took almost 50% of that payload, and to say the least, I was totally impressed by these large pellet results.

The Browning BPS that was selected for the salt marsh flats below New Orleans was shooting with poor barrel regulation and, as a result, shooting quite high. This being the case, admittedly I was a bit apprehensive about bringing it on the hunt. However, because the Browning was built like a bank vault and could take a real licking in the bottom of a mud boat if necessary, I made the decision to take it on the hunt versus my wood-stocked Winchester X3.

Mississippi Delta

As is often stated, “We make plans and God laughs.” While I can’t say exactly if luck or the powers of the universe had anything to do with it, but the weather we encountered at the edge of the Mississippi waters and the Gulf of Mexico were not a duck hunter’s friend. Dead calm, zero wind, bright sun and unpredictable low tides were owning the event right from the start.

With eight dozen decoys spread out by Cajun Adventures, our guiding service on this ballistics adventure, we did manage to pull in several flocks of wet birds and, as such, rolled out a few pintail and other assorted birds. With those shooting results, I managed to get a ballistic footprint associated with the new Briley Helix-based choke associated with the 1¼ oz. of Bismuth shot. The results were as expected when I missed a close-range bird with the long-range tube only to drop it clean as it pulled away from the decoy spread at high speed reaching the 40-yard downrange marker.

The duck shooting was fast and ended quickly with the rising sun. It was at that point that the owner and guide Ryan Lambert of Cajun Adventures suggested we might be better off spending our time hunting down nutria since it was low tide that produced mud flats, and the big aquatic rodents would be easier to spot on the channel banks. I have detailed this information because it set the scene for the gunning scenario that would become the working stage of the whole hunt.

Two elements also played a very important part in the event to follow. First, the load selection for nutria was upgraded to the 3″ 1 3/8 oz., #2 ITX using the Briley .030 Helix choke, and the backup gun was the Browning Gold in 10 gauge. The new ammunition was some of the first offered big bore hunters in the last decade by Backridge in 2 oz. payloads of again #2 ITX. While the primary gunning was being undertaken with the BPS and its paired loads, Kelly Haydel of Haydel’s Game Calls, and my partner Adam Ziegler, the Top Gun at Backridge Ammunition, both ran the 10-gauge backup guns.

As targets, the nutria are massive super rats as I call them. They weighed upward of 35 pounds with almost all of our harvested animals weighing in at over 20 pounds. The critter is a formidable warm-target test. Factoring in the $6 per tail bounty on each animal taken through the state of Louisiana and a wealth of good fur being taken at the prime time of the season, this was not just a pattern test but an enterprising hunting event.

Going Hot

Running an 18-foot mud boat up the inland waterways with a mud motor as our power source, we crossed shallow mud flats, sand bars and, after some time, found ourselves deep in the heart of the Mississippi Delta. The skipper got our attention when he yelled out, “We have a nutria target left at 45 yards near the bank.”

It was game on as the large black head came out of the water for a drink of air which produced a wide wake, allowing a good point of reference when sighting. Knowing the BPS shotgun shot high, I held on a 6 o’clock hold and touched off the 12 bore. At the shot, water catapulted high into the air. The pattern was lacking shot string and looked like someone had dropped a bucket of shot on the head of the nutria. This was the first 3-D look at the effects of the Helix payload control system. Paper patterns are only one dimension regarding performance. Now we had the almost complete picture right from the get-go.

Sending that first round downrange produced a level of confidence, and when the second target emerged at 30 yards it was game over in an instant. I had gunned two large nutria that weighed in at a total of 44 pounds. Not the single weight 35 pounders but very good examples of a very hard target. Each animal had only required one round of the #2 ITX #2 shot, which told me the choke was doing the job on target without question.

On the evening of that first day, it was the 10-gauge gun’s turn. With that, I was able to draw a comparison between the BPS loads in 12 bore 3″ and the massive, newly designed 3.5″ 10-gauge magnum rounds. Kelly took up the gun on the night shoot under lights and dusted off a large male, followed by Adam and the harvesting of still another large male. It seemed as though these big male targets were on the move for some reason.

Falling ill the same night, I did not shoot day two at all. But got bed rest for the long haul back into Kentucky and our final test base for the new choke system. On the boat that day, the guys still stayed with the Briley choke system in the .030 high performance Full and managed to dust off a total of ¼ ton of fur.

Getting back on my feet, I was present to photograph and observe the payload damage as the animals were skinned out for the fur market, and the tails removed for the bounty (guides got the payouts).

Water stops shot. Just try and take a wounded animal as a cripple in the water. Even so, the hits were almost always on the skull regarding the low-swimming targets. Penetration was very solid and, to be sure, the skull on an adult nutria is close to armor-plating. In this case, tungsten-based shot would have been the very best choice.

As a final roundup covering the new Briley choke system, we hunted Wildlife Management Area wetlands up north in Kentucky for our final event. That hunt yielded mallard ducks at 40 to 45 yards. This is an example of the range capability of the new Briley Helix waterfowl choke. Ed Sitton, a local freelance wetbird hunter, was kind enough to give us a ride on his mud boat into the Kentucky flooded lakes region managed by the U.S. Army Corps of Engineers. Hunting out of floating trap-door blinds as old as the 1950s, with some going back as far as 1943, the hunt was memorable as well as productive.

While I can’t say for sure the new Briley Helix waterfowl choke system did indeed compress the pellets to the core of the patterns, what I can say with certainty is the patterns were spot-on deadly. It would take 25,000 frames per second of ultra-high-speed photos to even begin to see the reaction of a shot column as it was exiting the choke to make any assumption as to the exact performance characteristics of the new choke system.

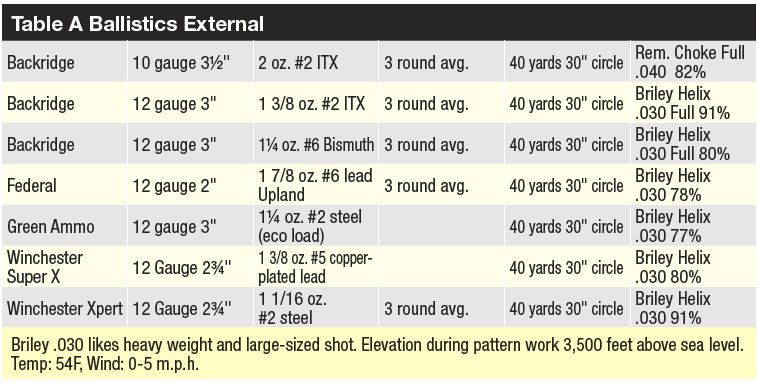

Included here is a basic pattern table that illustrates the pattern percentage results while testing a variety of current field load offerings in several types of shot.

Thanks to Backridge Ammunition for all their hard work in setting up this test event.

Thanks to Haydel’s Game Calls and my friend Kelly Haydel for bringing us together with Cajun Adventures. To Ryan Lambert, a heartfelt thank you for being our primary source for test subjects.

Thanks to Ed Sitton for offering up his duck camp as still another test base when reviewing the new Briley choke tube systems. SS

L.P. Brezny has worked in research and development in the shooting industry for 40 years. He developed and marketed the first sub-sonic shotgun and shotshell — The Hastings Metro Gun™ System (www.metrogun.com or 605-787-6321) — and was the first to measure shotshell pellets in real time at target distances, building ballistic tables demonstrating shotshell load performance and chronographing systems that are still in use today. He also developed the Dead Ringer® high-performance waterfowl/upland choke-tube system. L.P. has been writing for various shooting publications for over 35 years.